Facing Milky Hydraulic Oil? Here’s Your Solution!

Dealing with water-contaminated hydraulic oil can be a major headache, but you’re not alone. Many equipment owners struggle with this issue, seeking effective ways to restore their hydraulic systems. In this comprehensive guide, we’ll show you how to remove water from hydraulic oil and maintain optimal system performance.

Understanding Water Contamination in Hydraulic Oil

Water in hydraulic oil can cause serious damage, leading to system inefficiency and increased wear and tear. Signs of water contamination include oil that looks milky or cloudy. This guide covers:

- How to remove water from hydraulic fluid

- How to prevent water from entering hydraulic systems

Contact Hydraulic Specialty Inc. for Expert Assistance

How To Remove Water From Hydraulic Fluid

Removing water from hydraulic fluid requires understanding the various methods available:

- Vacuum Dehydration: This method involves using a vacuum to remove water by lowering its boiling point, effectively evaporating the moisture.

- Centrifugation: By spinning the hydraulic fluid at high speeds, this method separates water based on density differences.

- Absorption: Special filter elements can absorb water from hydraulic oil, ideal for minor contamination levels.

- Coalescence: This process involves separating water droplets from the oil, which then coalesce and are removed from the system.

Each method has its advantages and is suitable for different levels of water contamination. For severe cases, vacuum dehydration is often the most effective.

Is There An Additive To Remove Water From Hydraulic Oil?

Yes, there are additives specifically designed to remove or reduce water content in hydraulic oil. These additives work by absorbing water molecules, which are then filtered out. While additives can be effective for minor contamination, they may not address severe water issues and can have long-term impacts on oil quality and system health.

Explore Our Hydraulic Maintenance Services

How To Prevent Water From Entering Hydraulic Fluid

Preventing water contamination is crucial for maintaining the health of your hydraulic systems:

- Design Considerations: Ensure your system is designed to minimize exposure to moisture.

- Routine Maintenance: Regularly check for leaks and replace worn seals.

- Monitoring Techniques: Use moisture sensors to detect water contamination early.

- System Cleanliness: Keep your hydraulic system clean and properly sealed to prevent water ingress.

By following these best practices, you can significantly reduce the risk of water contamination in your hydraulic oil.

Contact Hydraulic Specialty For Expert Hydraulic Solutions

At Hydraulic Specialty Inc., we specialize in providing comprehensive hydraulic solutions. Whether you need help removing water from hydraulic oil or want to implement preventive measures, our experts are here to assist you. Contact us today for tailored hydraulic maintenance services.

By following this guide, you’ll not only resolve water contamination issues but also enhance the longevity and efficiency of your hydraulic systems. For more expert advice and solutions, don’t hesitate to reach out to Hydraulic Specialty Inc.

Internal Links:

- Are All Hydraulic Oils The Same?

- A Guide To Direct Acting Vs. Pilot Operated Relief Valves

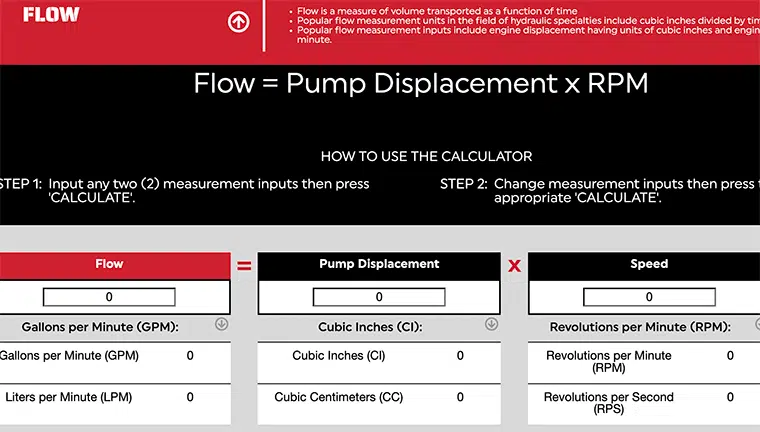

- All About Pressure & Flow: Working With Hydraulic Systems

- What Are The Components Of A Hydraulic System?

- How Does Temperature Affect Hydraulic Systems?

By incorporating these strategies and resources, you can maintain clean, efficient hydraulic systems and avoid the costly problems associated with water contamination. For any further assistance, contact Hydraulic Specialty Inc.